Product Description

Product Description

WAB series 220mm Shaft Output Slasher Reducer Planetary Gearbox FuBao

HangZhou Fubao Electromechanical Technology Co., Ltd. slasher gearbox speed reducer is a new generation of practical products independently developed by our company:

Low noise: less than 65db.

Low back clearance: up to 3 arc minutes in a CHINAMFG and 5 arc minutes in a double stage.

High torque: higher than the standard planetary reducer torque.

High stability: high strength alloy steel, the whole gear after hardening treatment, not only the surface hard substitution.

High deceleration ratio: Modular design, planetary gearbox can be interlinked.

slasher gearbox speed reducer characteristic:

1.Planetary reducer manufacturer-Fubao Electromechanical Technology adopts an integrated planetary carrier and output shaft, which can provide better torsional rigidity. After precision machining, the gear set is not easy to eccentric, which can reduce interference, reduce wear and noise, and at the same time use a large The bearings are arranged with a wide span to distribute the load of the bearings, and once again strengthen the torque rigidity and radial load capacity of the slasher gearbox speed reducer. The output cover is made of aluminum alloy, which provides better heat dissipation capability for the product, so that the reducer produced by Fubao Electromechanical Technology can play an excellent role in the field of mechanical tools.

2.The planetary gear set is specially made of alloy steel. First, it undergoes quenching and tempering heat treatment to make the material hardness reach HRC30 degrees, and then undergoes nitriding surface treatment to HV860, so that the product has the characteristics of high surface hardness and high toughness in the center, and achieves the best product strength and service life. optimization.

3.The input shaft and the motor output shaft are connected by a bolted structure, with a round shaft seal design, and through dynamic balance analysis, it can ensure that there is no eccentric load at high speeds. After reducing unnecessary radial force, it can effectively Reduce the load on the motor side.

4.The material of the input cover/motor connection seat is made of aluminum alloy, which can provide better heat dissipation effect, and then provide good concentricity and verticality through professional lathe processing, so that the product can be stably combined with various motors, reducing the damage caused by insufficient precision. Unnecessary axial radial force makes the product have a longer life cycle.

| WAB series parameters | Model number | WAB042 | WAB60 | WAB090 | WAB115 | WAB140 | WAB180 | WAB220 |

| Rated output torque | 14-22 | 23-60 | 48-160 | 140-330 | 342-650 | 520-1200 | 1140-2000 | |

| Reduction ratio | L1: 3, 4, 5, 6, 7, 8, 9, 10 L2: 15, 20, 25, 30, 35, 40, 50, 70, 80, 100 | |||||||

| Planetary gear backlash | L1: P0≤1 P1≤3 P2≤5 L2: P0≤3 P1≤5 P2≤7 | |||||||

Detailed Photos

Product Details

Other products

Product Advantage

Compared with other reduction machines, planetary gear reduction machines have high rigidity, high precision (single stage can be achieved within 1 point), high transmission efficiency (single stage in 97-98%), high torque/volume ratio, lifetime maintenance free and other characteristics.

Because of these characteristics, planetary gear reducer is mostly installed on the stepper motor and servo motor, used to reduce speed, increase torque, matching inertia.

Company Profile

HangZhou Fubao Electromechanical Technology Co., Ltd. was established in 2008, the company has a complete precision reducer design, production capacity. Set R & D, manufacturing, assembly and sales, more in the field of gear manufacturing has more than 10 years of background, in the manufacturing equipment is equipped with Switzerland Riesenhahl gear grinding machine, domestic Qinchuan gear grinding machine, hamai gear hobbing machine and domestic Xihu (West Lake) Dis. gear hobbing machine, Japan Yasaki TLGmazak CNC lathe, CNC milling machine and other fully CNC equipment, In addition, it is equipped with other advanced measuring equipment such as Japanese TTI gear detector, 3 coordinate measurement, reducer backlash measurement instrument and so on. In a strong manufacturing capacity at the same time, can be stable, continuous manufacturing of high-quality precision reducer products.

The precision reducer produced by our company has the characteristics of high structural rigidity, small back backlash, precise transmission and so on. It is widely used in various industries. Companies adhering to the concept of let customers participate in manufacturing, and strive to provide customers with more personalized services. In the field of precision transmission has a unique achievements. It is our CHINAMFG pursuit to make far-reaching contributions.

Factory Display

Q: Speed reducer grease replacement time

A: When sealing appropriate amount of grease and running reducer, the standard replacement time is 20000 hours according to the aging condition of the grease. In addition, when the grease is stained or used in the surrounding temperature condition (above 40ºC), please check the aging and fouling of the grease, and specify the replacement time.

Q: Delivery time

A: Fubao has 2000+ production base, daily output of 1000+ units, standard models within 7 days of delivery.

Q: Reducer selection

A: Fubao provides professional product selection guidance, with higher product matching degree, higher cost performance and higher utilization rate.

Q: Application range of reducer

A: Fubao has a professional research and development team, complete category design, can match any stepping motor, servo motor, more accurate matching.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Agricultural Machinery, Ball Screw Drive Shaft |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Customization: |

Available

| Customized Request |

|---|

What lubrication is required for screw gears?

Proper lubrication is essential for the efficient and reliable operation of screw gears, also known as worm gears. The lubrication requirements for screw gears depend on various factors, including the application, operating conditions, and the materials used in the gear system. Here’s a detailed explanation of the lubrication considerations for screw gears:

Selection of Lubricant:

When selecting a lubricant for screw gears, it is important to consider the following factors:

- Type of Lubricant: There are different types of lubricants available, such as oils, greases, and solid lubricants. The selection depends on factors such as operating speed, temperature range, load capacity, and environmental conditions. Consult the gear manufacturer’s recommendations or industry standards to determine the suitable lubricant type for the specific application.

- Viscosity: The lubricant viscosity should be chosen based on the operating conditions of the screw gear system. Higher viscosity lubricants are typically used for heavier loads or higher temperatures, while lower viscosity lubricants are suitable for lighter loads or lower temperatures. The viscosity should be within the range recommended by the gear manufacturer.

- Additives: Some lubricants contain additives that provide additional benefits, such as improved anti-wear properties, corrosion resistance, or extreme pressure protection. Consider the specific requirements of the screw gear system and choose a lubricant with suitable additives, if necessary.

Lubrication Guidelines:

Here are some general guidelines for lubricating screw gears:

- Initial Lubrication: Apply an appropriate amount of lubricant during the initial installation of the screw gear system. Ensure that all gear surfaces, including the worm and the worm wheel, are adequately coated with lubricant.

- Replenishment: Regularly monitor the lubricant level and condition of the screw gear system. Over time, lubricant may degrade, become contaminated, or lose its effectiveness. Follow the manufacturer’s recommendations for lubricant replenishment intervals and quantities. In some cases, lubricant replenishment may be necessary during routine maintenance.

- Proper Lubricant Distribution: Ensure that the lubricant is evenly distributed across the contacting surfaces of the screw gears. The lubricant should adequately cover the threads of the worm and the teeth of the worm wheel to reduce friction and wear. Proper lubricant distribution can be achieved through rotational movement of the gears or by applying the lubricant directly to the contact area.

- Prevent Excessive Lubrication: While proper lubrication is essential, excessive lubrication can lead to problems such as overheating, increased drag, and leakage. Follow the manufacturer’s recommendations regarding the appropriate lubricant quantity. Avoid over-greasing or over-oiling the screw gear system.

- Cleanliness: Maintain cleanliness when lubricating screw gears. Ensure that the lubrication equipment, such as grease guns or oilers, is clean and free from contaminants. Contaminants, such as dirt or debris, can compromise the lubricant’s performance and increase wear on the gears.

It is important to note that the lubrication requirements may vary based on the specific screw gear system and its operating conditions. Therefore, always refer to the gear manufacturer’s recommendations and guidelines for the most accurate and up-to-date information regarding lubrication requirements.

How do you address thermal expansion and contraction in a screw gear system?

Addressing thermal expansion and contraction in a screw gear system is crucial to ensure the proper functioning and longevity of the system. Thermal expansion and contraction occur when a system is subjected to temperature changes, leading to dimensional changes in the components. Here’s a detailed explanation of how to address thermal expansion and contraction in a screw gear system:

- Material Selection: Choose materials for the screw gear system components that have compatible coefficients of thermal expansion (CTE). Using materials with similar CTE can help minimize the differential expansion and contraction between the components, reducing the potential for misalignment or excessive stress. Consider materials such as steel, bronze, or other alloys that exhibit good dimensional stability over the expected operating temperature range.

- Design for Clearance: Incorporate proper clearances and tolerances in the design of the screw gear system to accommodate thermal expansion and contraction. Allow for sufficient clearance between mating components to accommodate the expected dimensional changes due to temperature variations. This can prevent binding, excessive friction, or damage to the gears during temperature fluctuations.

- Lubrication: Utilize appropriate lubrication in the screw gear system to mitigate the effects of thermal expansion and contraction. Lubricants can help reduce friction, dissipate heat, and provide a protective film between the mating surfaces. Select lubricants that offer good thermal stability and maintain their properties across the expected temperature range of the system.

- Thermal Insulation: Implement thermal insulation measures to minimize the exposure of the screw gear system to rapid temperature changes. Insulating the system from external heat sources or environmental temperature fluctuations can help reduce the thermal stresses and minimize the effects of expansion and contraction. Consider using insulating materials or enclosures to create a more stable temperature environment around the screw gear system.

- Temperature Compensation Mechanisms: In certain applications, it may be necessary to incorporate temperature compensation mechanisms into the screw gear system. These mechanisms can actively or passively adjust the position or clearance between components to compensate for thermal expansion or contraction. Examples include thermal expansion compensation screws, bimetallic elements, or other devices that can accommodate dimensional changes and maintain proper alignment under varying temperatures.

- Operational Considerations: Take into account the thermal characteristics of the environment and the operational conditions when using a screw gear system. If the system is expected to experience significant temperature variations, ensure that the operating parameters, such as load capacities and operating speeds, are within the design limits of the system under the anticipated temperature range. Monitor and control the temperature of the system if necessary to minimize the effects of thermal expansion and contraction.

- System Testing and Analysis: Conduct thorough testing and analysis of the screw gear system under various temperature conditions to assess its performance and behavior. This can involve measuring dimensional changes, analyzing gear meshing characteristics, and evaluating the system’s ability to maintain proper alignment and functionality. Use the test results to validate the design, make any necessary adjustments, and optimize the system’s performance under thermal expansion and contraction effects.

- Maintenance and Inspection: Establish a regular maintenance and inspection routine for the screw gear system to monitor its performance and address any issues related to thermal expansion and contraction. This can involve checking clearances, lubrication levels, and the overall condition of the system. Promptly address any signs of excessive wear, misalignment, or abnormal operation that may be attributed to temperature-related effects.

By considering material selection, design clearances, lubrication, thermal insulation, temperature compensation mechanisms, operational considerations, and regular maintenance, it is possible to effectively address thermal expansion and contraction in a screw gear system. These measures help ensure the system’s reliability, minimize wear and damage, and maintain the desired performance and functionality over a range of operating temperatures.

What is a screw gear and how does it work?

A screw gear, also known as a worm gear, is a type of gear mechanism that consists of a screw-like gear (called the worm) and a toothed wheel (called the worm wheel or worm gear). The screw gear operates on the principle of a helical screw driving a toothed wheel to transmit rotational motion and power. Here is a detailed explanation of how a screw gear works:

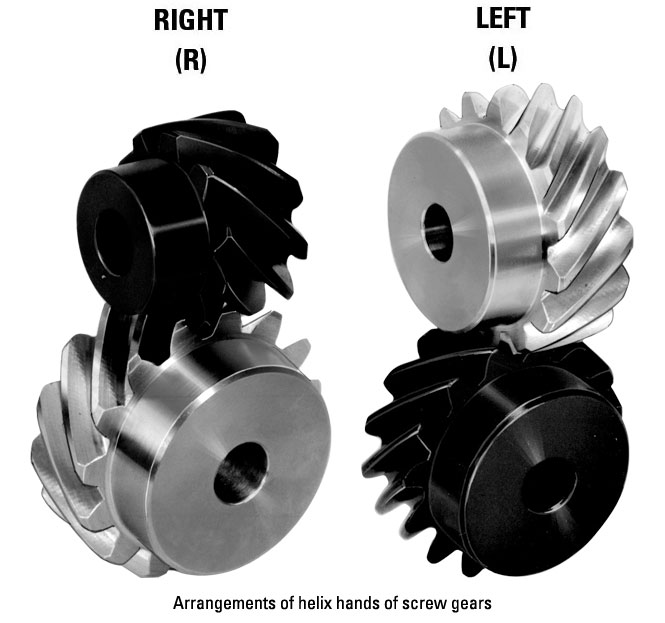

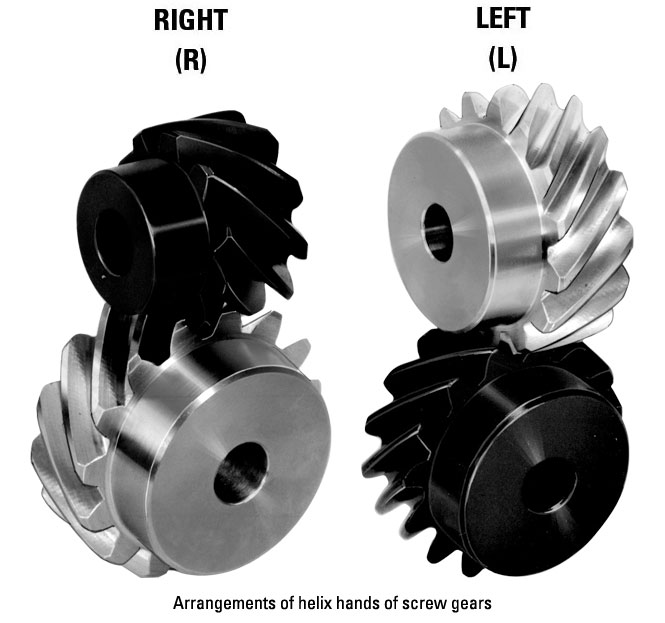

- Configuration: The screw gear consists of two main components: the worm and the worm wheel. The worm is a cylindrical gear with a helical thread wrapped around it, resembling a screw. The worm wheel is a toothed wheel that meshes with the worm. The orientation of the helical thread on the worm and the teeth on the worm wheel is typically perpendicular to each other.

- Meshing: The worm and the worm wheel mesh together by engaging the helical thread of the worm with the teeth of the worm wheel. The helical thread on the worm acts as a screw, and as the worm rotates, it drives the rotation of the worm wheel. The teeth on the worm wheel provide the necessary contact points for the meshing action.

- Transmitting Motion: When the worm rotates, the helical thread transfers rotational motion to the worm wheel. The helical thread of the worm pushes against the teeth of the worm wheel, causing the worm wheel to rotate. The direction of rotation of the worm wheel depends on the helix angle and the direction of rotation of the worm. The gear ratio between the worm and the worm wheel is determined by the number of teeth on the worm wheel and the pitch of the helical thread on the worm.

- Mechanical Advantage: One of the key characteristics of a screw gear is its ability to provide a high mechanical advantage or gear ratio. The helical design of the worm and the worm wheel allows for a large number of teeth to be engaged at any given time, resulting in a high gear ratio. This makes screw gears suitable for applications that require a significant reduction in rotational speed or an increase in torque.

- Self-Locking: A unique property of screw gears is their self-locking capability. Due to the helical thread design, the friction between the worm and the worm wheel tends to hold the gear system in place when the worm is not rotating. This self-locking characteristic prevents the worm wheel from backdriving the worm. It provides inherent braking or locking action, making screw gears suitable for applications where holding position or preventing reverse rotation is necessary.

- Efficiency and Lubrication: Screw gears generally have lower efficiency compared to other types of gears due to the sliding action between the helical thread and the teeth of the worm wheel. The sliding motion results in higher friction and heat generation. Proper lubrication is essential to minimize wear and improve efficiency. Lubricants with good adhesion and boundary lubrication properties are commonly used for screw gears.

Screw gears are widely used in various applications, including machinery, automotive systems, conveyor systems, lifting equipment, and many others. Their unique characteristics of high gear ratio, self-locking capability, and compact design make them suitable for specific applications where precise motion control, torque multiplication, or holding position is required.

editor by CX 2023-09-23