Product Description

| Product Model | SWL2.5, SWL5, SWL10, SWL15, SWL20, SWL25, SWL35, SWL50, SWL100, SWL120 |

| Product Description | Basic lifting component, compact structure, small size, light weight, no noise, safe and convenient, flexible use, high reliability, wide power source, multiple supporting functions, long service life |

| Usage | Single or combined use, can accurately control the adjustment of lifting or pushing height according to a certain program, can be directly driven by motor or other power, can also be manual |

| Lifting Efficiency and Load Capacity | Special and advanced technology has been developed to improve the overall performance of the jack |

| Structural Type | Type 1 – Screw moves axially; Type 2 – Screw rotates, nut moves axially |

| Assembly Type | Type A – Screw/nut moves upwards; Type B – Screw/nut moves downwards |

| Screw Head Type | Type 1 structure screw head: Type I (cylindrical), Type II (flange), Type III (threaded), Type IV (flat head); Type 2 structure screw head: Type I (cylindrical), Type III (threaded) |

| Transmission Ratio | Ordinary speed ratio (P), slow speed ratio (M), medium speed ratio (F) can be customized according to user requirements |

| Lifting Load Capacity | 2.5kN, 5kN, 10kN, 15kN, 20kN, 25kN, 35kN, 50kN, 100kN, 120kN |

| Screw Protection | Type 1 structure: basic type (no protection), anti-rotation type (F), with protective cover (Z), anti-rotation and protective cover (FZ); Type 2 structure: basic type (no protection) |

Product description: SWL series worm gear screw lift is a basic lifting component with many advantages such as compact structure, small volume, light weight, no noise, safety and convenience, flexible use, high reliability, wide power source, many supporting functions and long service life. It can be used singly or in combination, can adjust the height of lifting or advancing accurately according to certain procedures, and can be driven directly by electric motor or other power, or manually. In order to improve the efficiency and carrying capacity of SWL series worm gear screw lift, special and advanced technology is developed to improve the comprehensive performance of the lift to meet the requirements of the majority of customers. SWL series worm gear screw lift has different structure types and assembly types, and the lifting height can be customized according to the user’s requirements.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Standard or Nonstandard: | Nonstandard |

|---|---|

| Application: | Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car |

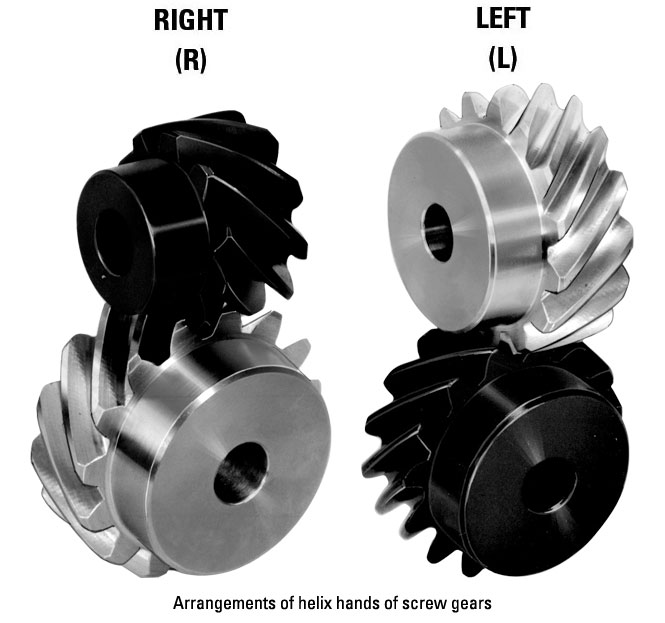

| Spiral Line: | Right-Handed Rotation |

| Head: | Single Head |

| Reference Surface: | Toroidal Surface |

| Type: | ZK Worm |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Are screw gears suitable for high-torque applications?

Using screw gears, also known as worm gears, in high-torque applications requires careful consideration. The torque capacity of screw gears can be a limiting factor due to their unique design and characteristics. Here’s a detailed explanation of the suitability of screw gears for high-torque applications:

Yes, screw gears can be suitable for high-torque applications, but there are certain limitations to consider:

- Lower Torque Capacity: Screw gears generally have a lower torque capacity compared to other gear types, such as spur gears or helical gears. The sliding contact between the worm gear and worm wheel, coupled with the high gear ratios typically associated with screw gears, can result in higher contact stresses and increased wear. Therefore, screw gears are generally not the first choice for applications with extremely high torque requirements.

- Efficiency and Heat Generation: In high-torque applications, the efficiency of the gear system becomes crucial. Screw gears, due to their sliding motion and higher friction compared to other gear types, can have lower mechanical efficiency. This lower efficiency leads to increased heat generation, which may be a concern in high-torque applications where heat dissipation becomes challenging. Proper lubrication, cooling, and heat management strategies are important to ensure reliable operation under high torque conditions.

- Load Distribution: The load distribution in a screw gear mechanism is not as uniform as in some other gear types. The load is concentrated on a limited number of teeth, which can lead to higher tooth stresses and potential wear. This concentration of load can be a limiting factor in high-torque applications, as it can result in premature gear failure or reduced lifespan.

- Application-Specific Considerations: While screw gears may have limitations in high-torque applications, there are scenarios where they can still be suitable. For example, in applications that require precise positioning, heavy loads, or the ability to hold position without additional braking mechanisms, the self-locking feature of screw gears can be advantageous. Additionally, advancements in gear design, materials, and lubrication can help improve the torque capacity and performance of screw gears in specific high-torque applications.

When considering the use of screw gears in high-torque applications, it is important to carefully evaluate the specific torque requirements, operating conditions, and other factors such as speed, duty cycle, and environmental considerations. Consulting with experienced engineers and conducting thorough analysis will help determine whether screw gears are suitable or if alternative gear types should be considered to meet the high-torque demands of the application.

How do you address thermal expansion and contraction in a screw gear system?

Addressing thermal expansion and contraction in a screw gear system is crucial to ensure the proper functioning and longevity of the system. Thermal expansion and contraction occur when a system is subjected to temperature changes, leading to dimensional changes in the components. Here’s a detailed explanation of how to address thermal expansion and contraction in a screw gear system:

- Material Selection: Choose materials for the screw gear system components that have compatible coefficients of thermal expansion (CTE). Using materials with similar CTE can help minimize the differential expansion and contraction between the components, reducing the potential for misalignment or excessive stress. Consider materials such as steel, bronze, or other alloys that exhibit good dimensional stability over the expected operating temperature range.

- Design for Clearance: Incorporate proper clearances and tolerances in the design of the screw gear system to accommodate thermal expansion and contraction. Allow for sufficient clearance between mating components to accommodate the expected dimensional changes due to temperature variations. This can prevent binding, excessive friction, or damage to the gears during temperature fluctuations.

- Lubrication: Utilize appropriate lubrication in the screw gear system to mitigate the effects of thermal expansion and contraction. Lubricants can help reduce friction, dissipate heat, and provide a protective film between the mating surfaces. Select lubricants that offer good thermal stability and maintain their properties across the expected temperature range of the system.

- Thermal Insulation: Implement thermal insulation measures to minimize the exposure of the screw gear system to rapid temperature changes. Insulating the system from external heat sources or environmental temperature fluctuations can help reduce the thermal stresses and minimize the effects of expansion and contraction. Consider using insulating materials or enclosures to create a more stable temperature environment around the screw gear system.

- Temperature Compensation Mechanisms: In certain applications, it may be necessary to incorporate temperature compensation mechanisms into the screw gear system. These mechanisms can actively or passively adjust the position or clearance between components to compensate for thermal expansion or contraction. Examples include thermal expansion compensation screws, bimetallic elements, or other devices that can accommodate dimensional changes and maintain proper alignment under varying temperatures.

- Operational Considerations: Take into account the thermal characteristics of the environment and the operational conditions when using a screw gear system. If the system is expected to experience significant temperature variations, ensure that the operating parameters, such as load capacities and operating speeds, are within the design limits of the system under the anticipated temperature range. Monitor and control the temperature of the system if necessary to minimize the effects of thermal expansion and contraction.

- System Testing and Analysis: Conduct thorough testing and analysis of the screw gear system under various temperature conditions to assess its performance and behavior. This can involve measuring dimensional changes, analyzing gear meshing characteristics, and evaluating the system’s ability to maintain proper alignment and functionality. Use the test results to validate the design, make any necessary adjustments, and optimize the system’s performance under thermal expansion and contraction effects.

- Maintenance and Inspection: Establish a regular maintenance and inspection routine for the screw gear system to monitor its performance and address any issues related to thermal expansion and contraction. This can involve checking clearances, lubrication levels, and the overall condition of the system. Promptly address any signs of excessive wear, misalignment, or abnormal operation that may be attributed to temperature-related effects.

By considering material selection, design clearances, lubrication, thermal insulation, temperature compensation mechanisms, operational considerations, and regular maintenance, it is possible to effectively address thermal expansion and contraction in a screw gear system. These measures help ensure the system’s reliability, minimize wear and damage, and maintain the desired performance and functionality over a range of operating temperatures.

How do screw gears contribute to linear motion and power transmission?

Screw gears, also known as worm gears, play a significant role in achieving linear motion and power transmission in various mechanical systems. Here’s a detailed explanation of how screw gears contribute to these functions:

Linear Motion:

Screw gears can convert rotary motion into linear motion or vice versa through the interaction between the worm and the worm wheel. The helical threads on the worm and the teeth on the worm wheel create a sliding and rolling contact that results in linear displacement along the axis of the screw. This mechanism enables precise control and positioning of linear motion in different applications.

The linear motion contribution of screw gears can be observed in the following scenarios:

- Lead Screw Mechanisms: When the worm gear is used as a lead screw, it converts the rotary motion of the worm into linear motion along the screw’s axis. By rotating the worm, the worm wheel moves linearly, allowing for controlled and precise linear positioning. Lead screw mechanisms are widely used in applications such as CNC machines, 3D printers, and linear actuators.

- Linear Motion Conversion: In certain applications, the linear motion of a load can be converted into rotary motion using screw gears. By fixing the worm wheel and applying linear force to the worm, the rotation of the worm can drive the rotary motion of other components. This conversion is utilized in applications such as conveyor systems, lifting mechanisms, and material handling equipment.

Power Transmission:

Screw gears are effective in power transmission due to their unique characteristics. Here’s how they contribute to power transmission:

- Gear Reduction: Screw gears provide significant gear reduction, which is the ratio between the input speed and the output speed. This reduction allows for a smaller input speed to generate a larger output torque, making screw gears suitable for applications requiring high torque and low-speed rotation. The gear reduction capability of screw gears enables efficient power transmission, especially in scenarios where high torque is necessary.

- Torque Multiplication: Through the interaction of the helical threads on the worm and the teeth on the worm wheel, screw gears multiply torque. The mechanical advantage gained through the screw gear mechanism enables the transmission of higher torque to drive loads with increased force. This torque multiplication is essential in applications that require heavy lifting, load handling, and power transmission with minimal slippage.

By combining the ability to convert rotary motion into linear motion and providing efficient power transmission, screw gears find widespread use in a range of applications. They are employed in industries such as manufacturing, automation, robotics, material handling, and various other systems that require precise linear motion control and effective power transmission.

editor by CX 2023-09-05